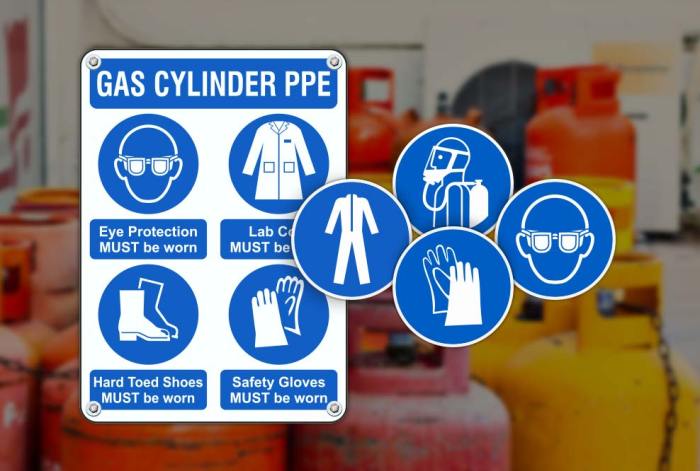

Is a partial cylinder ppe – Partial cylinder PPE, a vital element in the realm of protective equipment, safeguards workers from occupational hazards. Its unique shape and robust materials provide a reliable barrier against impact, punctures, and chemical exposure, ensuring the well-being of individuals in hazardous work environments.

Partial cylinders find applications in diverse industries, from construction and manufacturing to mining and healthcare. They form an integral part of hard hats, safety goggles, and other protective gear, offering a combination of comfort and protection.

Definition and Properties of a Partial Cylinder

A partial cylinder is a three-dimensional shape formed by cutting a section from a complete cylinder. It is characterized by a curved surface and two parallel circular bases, with the height being the distance between the bases.

The mathematical representation of a partial cylinder in Cartesian coordinates is given by the equation:

$$(x-h)^2+y^2=r^2, \quad 0\le z\le H$$where (h, 0) is the center of the circular bases, r is the radius of the bases, and H is the height of the partial cylinder.

Key Characteristics and Properties

The key characteristics and properties of a partial cylinder include:

- Curved surface area: The curved surface area of a partial cylinder is given by $$2\pi rh$$, where r is the radius of the bases and h is the height.

- Volume: The volume of a partial cylinder is given by $$V=\pi r^2 h$$, where r is the radius of the bases and h is the height.

- Lateral surface area: The lateral surface area of a partial cylinder is the area of the curved surface, which is given by $$2\pi rh$$.

Examples of Real-World Objects

Partial cylinders can be found in various real-world objects, such as:

- Drinking glasses

- Cylindrical containers with lids

- Tunnels

- Pipelines

Applications of Partial Cylinders

Partial cylinders find widespread use across various industries and applications, contributing to both functionality and aesthetics. In engineering, they are employed in structural components, such as beams and columns, providing strength and stability. They are also utilized in construction, where they form the basis of arches, vaults, and domes, adding architectural interest and grandeur.

In Engineering

Partial cylinders serve as key elements in engineering structures, particularly in the construction of bridges, buildings, and machinery. Their curved shape enables efficient distribution of forces, making them suitable for load-bearing applications. They are also used in fluid mechanics, where they form the basis of pipes, ducts, and tanks, facilitating the flow and containment of liquids and gases.

In Construction

Partial cylinders are extensively employed in construction, adding both structural integrity and aesthetic appeal. Arches, formed by two or more partial cylinders, are commonly used in bridges, providing support and allowing for wider spans. Vaults, created by intersecting partial cylinders, form the ceilings of many historical buildings, offering both strength and architectural elegance.

Domes, constructed from a series of partial cylinders, are iconic structures that adorn many religious and public buildings, providing ample space and a distinctive silhouette.

In Design

Partial cylinders are not limited to structural applications but also play a significant role in design. In furniture design, they are used to create curved surfaces, adding visual interest and ergonomic comfort. In product design, they form the basis of containers, packaging, and other objects, providing both functionality and aesthetic appeal.

In automotive design, partial cylinders are used in body panels, fenders, and spoilers, contributing to the overall shape and aerodynamics of vehicles.

Fabrication and Manufacturing of Partial Cylinders

Partial cylinders can be fabricated and manufactured using various methods, each with its advantages and limitations. The choice of method depends on factors such as the desired dimensions, tolerance requirements, and material properties.

Materials

Partial cylinders can be made from a wide range of materials, including metals, plastics, and composites. The selection of material depends on the intended application and the required properties, such as strength, durability, and corrosion resistance.

Processes, Is a partial cylinder ppe

Common fabrication methods for partial cylinders include:

-

-*Rolling

Is a partial cylinder ppe? Well, it’s a bit of a tricky question, but you can find more information on this topic by checking out the saxon math course 2 pdf . That document has a lot of great information on the topic, and it’s definitely worth checking out if you’re interested in learning more.

After reading the pdf, come back here to continue learning about is a partial cylinder ppe.

Sheet metal is rolled into a cylindrical shape and then cut to the desired length.

-*Bending

A flat sheet of material is bent into a cylindrical shape using a press brake or other bending machine.

-*Casting

Molten metal is poured into a mold and allowed to solidify into the desired shape.

-*Machining

A solid cylinder is machined to remove material and create the desired shape.

-*3D printing

A 3D printer can be used to create complex partial cylinder shapes from various materials.

Challenges

Fabricating partial cylinders with specific dimensions and tolerances can be challenging. Factors that can affect the accuracy and quality of the finished product include:

- Material properties

- Process limitations

- Tooling accuracy

- Environmental conditions

Design Considerations for Partial Cylinders: Is A Partial Cylinder Ppe

Designing partial cylinders requires careful consideration of various factors to ensure they meet specific application requirements. Material properties, dimensions, and loading conditions play crucial roles in the design process.

Material Properties

- The material chosen for the partial cylinder should possess the necessary strength, stiffness, and durability to withstand the anticipated loads and environmental conditions.

- Factors such as yield strength, tensile strength, and fatigue resistance must be considered.

Dimensions

- The dimensions of the partial cylinder, including the radius, height, and thickness, must be carefully determined based on the required strength, stiffness, and weight constraints.

- The aspect ratio (ratio of height to radius) affects the cylinder’s stability and load-bearing capacity.

Loading Conditions

- The type and magnitude of loading conditions (e.g., axial, bending, torsional) must be considered to ensure the partial cylinder can withstand the expected loads without failure.

- The design must account for both static and dynamic loads, as well as any potential impact or fatigue loads.

By carefully considering these factors and applying appropriate design guidelines and best practices, engineers can design partial cylinders that meet specific requirements for strength, stiffness, and durability.

Computational Analysis of Partial Cylinders

Computational analysis plays a crucial role in comprehending the intricate behavior of partial cylinders. It enables engineers to predict stress, strain, and deformation under various loading conditions, optimizing designs and ensuring structural integrity.

The finite element method (FEM) is a widely used technique for analyzing partial cylinders. FEM discretizes the cylinder into small elements, allowing for detailed stress and strain calculations at each element. Other techniques include boundary element methods (BEM) and analytical methods.

Advantages of Computational Analysis

- Predictive capabilities: Computational analysis can predict the behavior of partial cylinders under complex loading scenarios, providing valuable insights for design optimization.

- Detailed stress and strain analysis: FEM enables the calculation of stress and strain at specific locations within the cylinder, helping identify critical areas and potential failure points.

- Optimization of designs: Computational analysis allows for iterative design modifications, optimizing the shape, thickness, and material properties of partial cylinders for improved performance.

Limitations of Computational Analysis

- Accuracy depends on model assumptions: The accuracy of computational analysis relies on the assumptions made in the model, such as material properties, boundary conditions, and loading scenarios.

- Computational cost: FEM analysis can be computationally expensive, especially for complex geometries and large models.

- Interpretation of results: Interpreting the results of computational analysis requires expertise in structural mechanics and familiarity with the limitations of the analysis techniques used.

Popular Questions

What is the purpose of partial cylinder PPE?

Partial cylinder PPE is designed to protect workers from impact, punctures, and chemical hazards.

In what industries are partial cylinder PPE commonly used?

Partial cylinder PPE is widely used in construction, manufacturing, mining, and healthcare.

What materials are used to make partial cylinder PPE?

Partial cylinder PPE is typically made from durable materials such as polycarbonate, polyethylene, and fiberglass.